3 000-Head Dairy Farm: Turning Manure into Hygienic Bedding

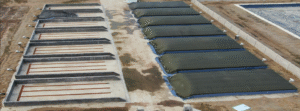

Case Study | XINING, QINGHAI 1 . Project Background A large dairy farm in Xining keeps >3 000 Holstein cows, producing nearly 40 t of manure every day. Traditional windrow composting for fertiliser was slow and labour-intensive, while the farm still spent heavily on sawdust bedding each year. In early 2024 management chose a circular “manure-to-bedding” model to cut costs and improve sustainability. 2 . Jiesonglin Solution After extensive evaluation the farm installed six 200 m³ e-PTFE membrane composters from Jiesonglin Technology. The closed aerobic process works as follows: 3 . Proven Results KPI Value Composting cycle ≤ 25 days Annual bedding output ≈ 2 000 t Bedding cost reduction > 30 % (≈ CNY 200 000 saved/yr) Animal health impact Lower mastitis rate, higher milk yield The recycled bedding is highly absorbent and comfortable, enhancing udder hygiene and cow welfare. 4 . Customer Testimonial “These composters solved our manure headache and slashed bedding expenses.The cows like the soft, dry material, and we’re thrilled to turn waste into real value.”— Farm Manager, Xining Dairy 5 . Demonstration Value This project sets a “Xining model” for high-altitude dairy regions, showcasing efficient manure utilisation, cost savings and greener livestock production on the Qinghai-Tibet Plateau.