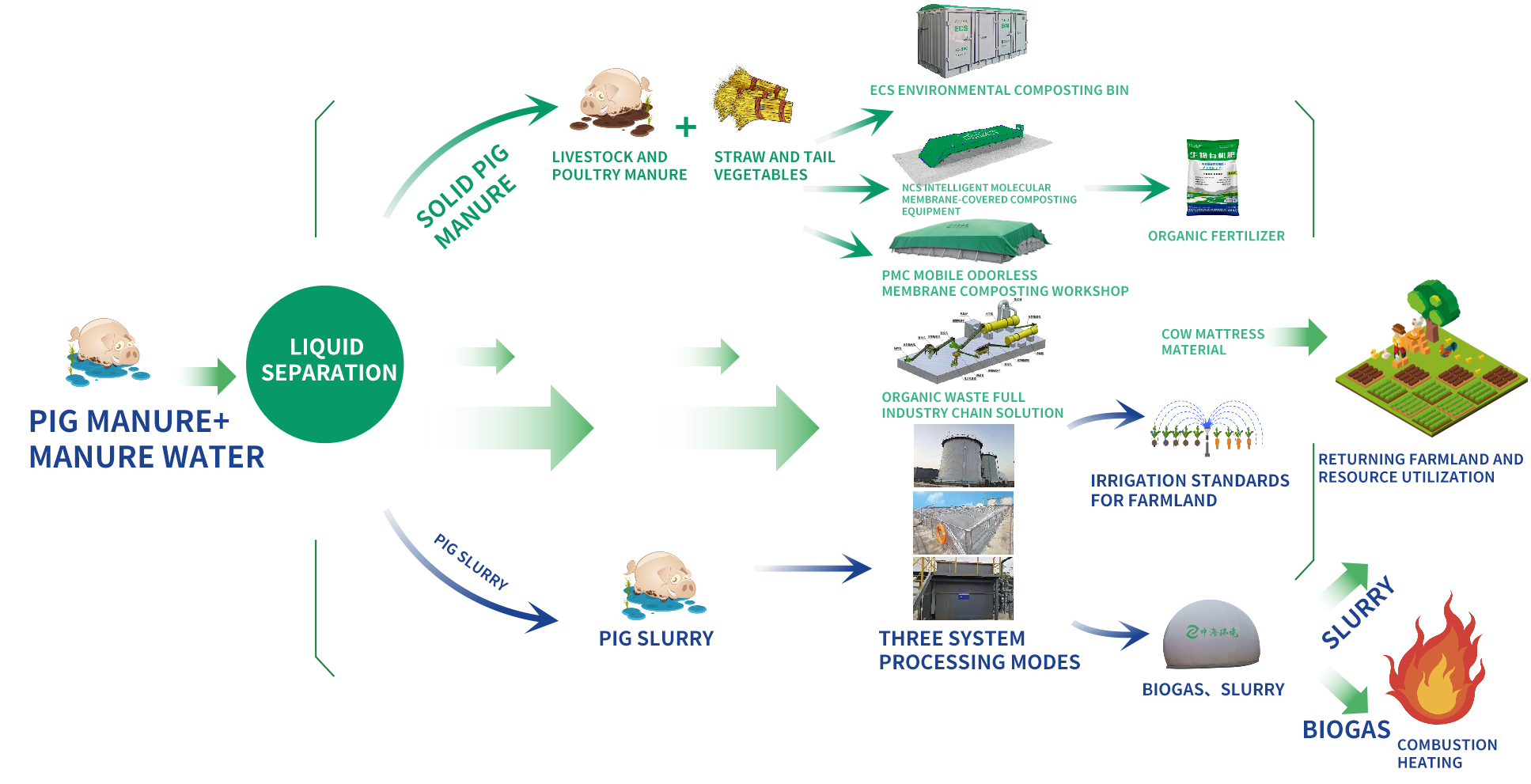

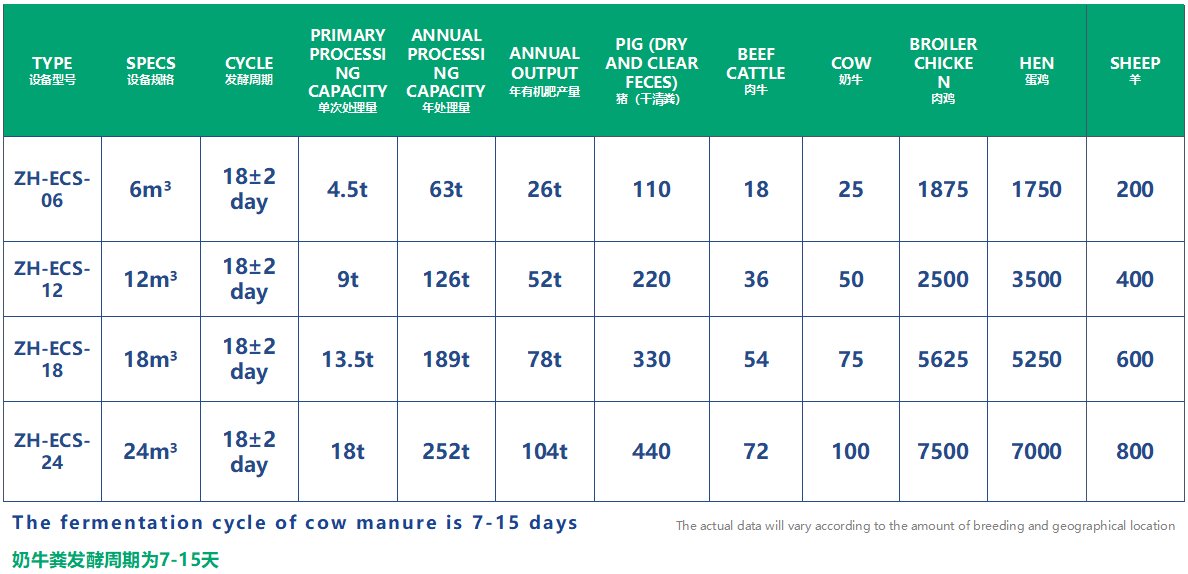

| Solution for the entire industry chain of pig manure treatment |

| Technical route for aerobic composting of pig manure |

|  |  |

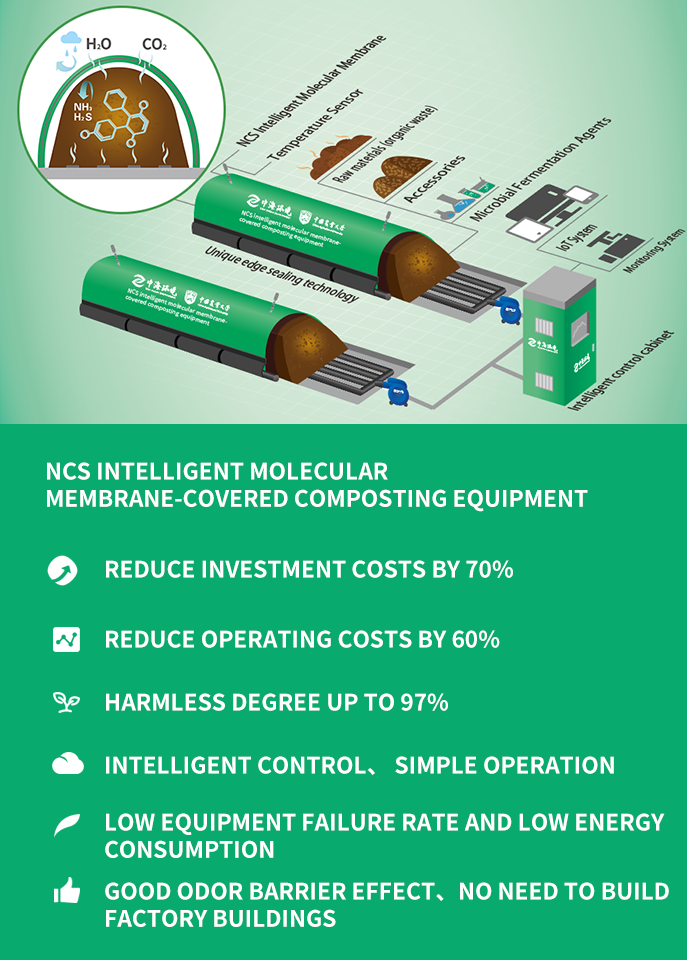

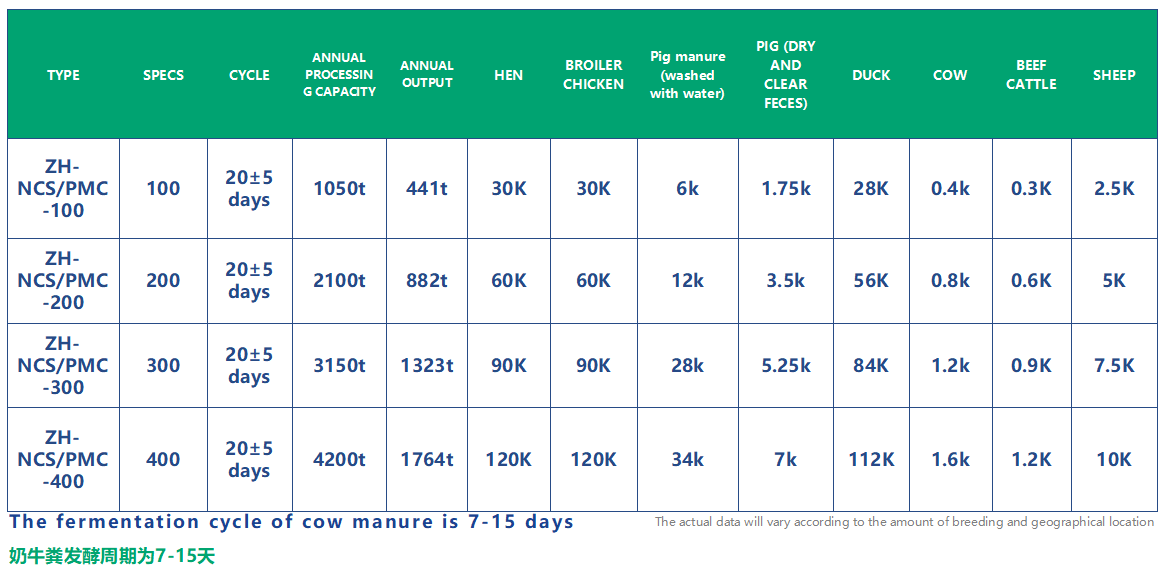

| Supporting equipment for the entire industry chain |

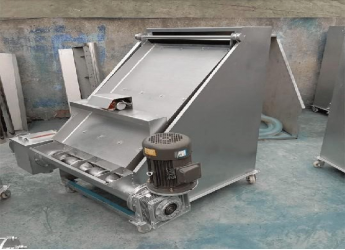

Solid liquid separation equipment

|  |

| Inclined screen solid-liquid separator | Stacked screw sludge dewatering machine |

Fermentation auxiliary equipment

|  |  |  |

| Wall mounted film rolling machine | Self propelled flipping machine | Slot type laminating flipping and throwing machine | Self propelled laminating and flipping machine |

Low cost, low-carbon, fully automatic organic fertilizer production line

|  |  |  |  |

| Storage bin | Grinder | Screening Machine | Granulator | Packer |

Fertilization and returning facilities and equipment

|  |  |

| Double vertical dragon fertilizer spreader | Double disc fertilizer spreader | Liquid fertilizer spreader |

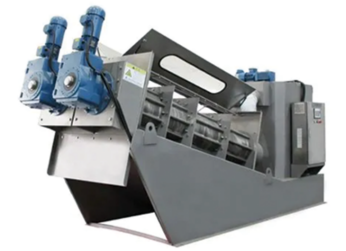

| Livestock manure water treatment equipment |

Three system processing (USR/UASB+two-level AO/three-level AO+MBR+Fenton/ozone)

Single system:

USR/UASB/CSTR: Generate biogas slurry fertilizer and biogas

Biogas is used for heating, and biogas slurry is returned to the field for utilization; Centralized treatment of manure and water reduces investment in manure treatment facilities in breeding farms.

Dual system:

USR/UASB+two-stage AO: generating biogas slurry fertilizer+irrigation water for farmland

The biogas slurry is first used for land consumption; If there is not enough land, it can be directly used to generate irrigation water for farmland.

Three systems:

USR/UASB+tertiary AO+MBR+Fenton/ozone, generating biogas slurry fertilizer+agricultural irrigation water+primary A river discharge water

If there is not enough surrounding land, it can be directly discharged into the river through Level A discharge treatment.

Small integrated fecal water treatment equipment

Processing type:

Discharge aquaculture wastewater for small-scale breeding facilities.

Discharge standard:

The effluent quality meets the dryland water quality indicators of the “Irrigation Water Quality Standards for Farmland (GB 5084-2021)”, and the project utilizes manure water as a resource.

Scope of application:

Small and medium-sized livestock farms, small-scale manure and water treatment projects, rural toilet renovation projects, etc. Discharge standard: The effluent quality meets the dryland water quality indicators specified in the “Irrigation Water Quality Standards for Farmland (GB 5084-2021)”, and the project utilizes manure water as a resource.

Good processing effect:

The materials in the reaction zone are fluidized by the action of biogas and reflux water, which enhances the surface contact between sludge and water.

Equipped with a baffle:

Can maintain the concentration of sludge in the reaction zone, prevent sludge loss, and maintain reaction efficiency.

High equipment load:

Sludge thus maintains high activity and can withstand high sludge loads.

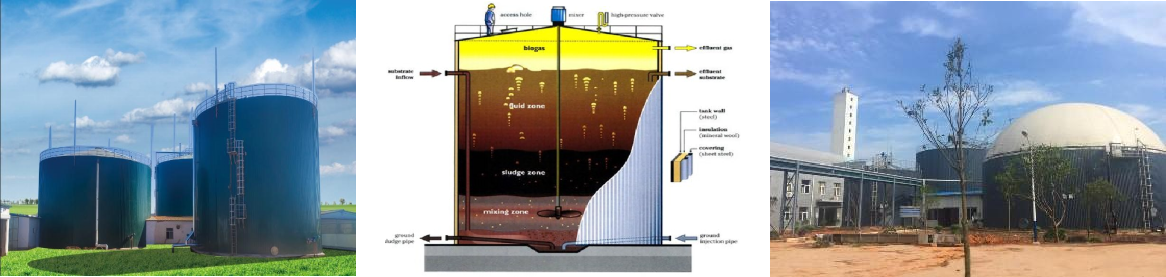

Biogas Equipment – Wet Anaerobic Fermentation CSTR Process

Mature and reliable technology:

Adopting wet anaerobic fermentation process, the treatment technology is mature.

Strong resistance to system impact:

The system uses impact resistant materials that provide protection against internal impacts.

Simple operation:

Easy to operate, no need for too many steps, high volumetric gas production rate.

Low energy consumption during processing:

Equipped with an intelligent control system, it is easy to operate and reduces operating and investment costs.